Computerized Maintenance Management System

Probably the only program you need in the Maintenance Department

PREVENTING BREAKDOWNS

Identification of failure causes, a convenient calendar of inspections and repairs

EFFICIENT COMMUNICATION

A multi-level notification escalation system, a handy instant messenger

LOWER RUNNING COSTS

Control of service and repair costs, optimal stock levels

GREATER EFFICIENCY

Management of employees’ working time and servicing tasks

The best Maintenance Management Departments work quickly and efficiently

One system that gathers information about all production lines and machines. One system for reporting and handling every event. One task schedule that provides appropriate prevention level.

ProCMMS Computerized Maintenance Management System - probably the only system you need.

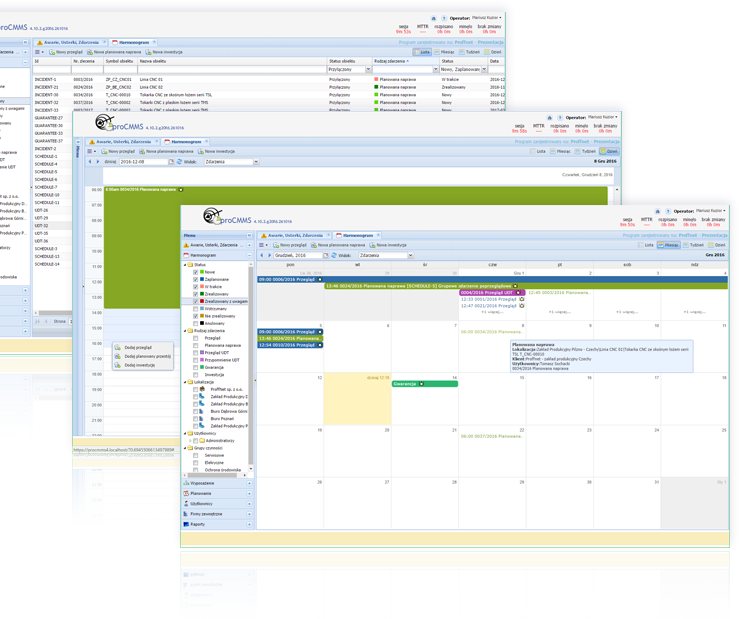

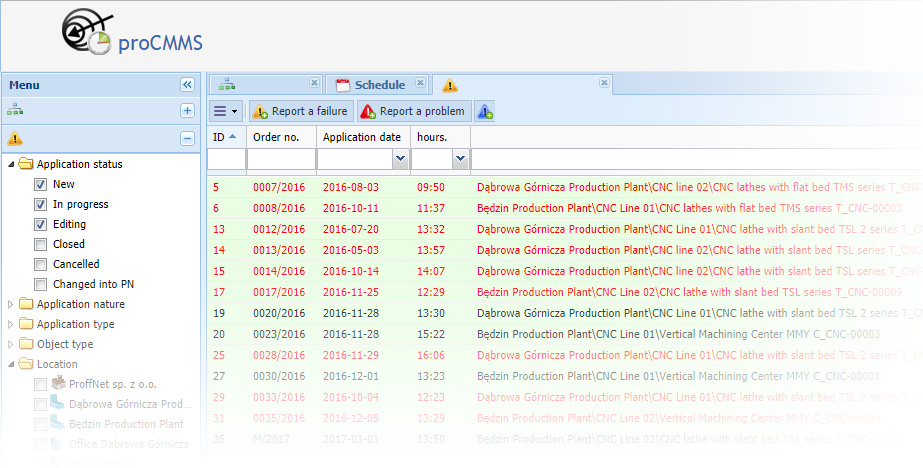

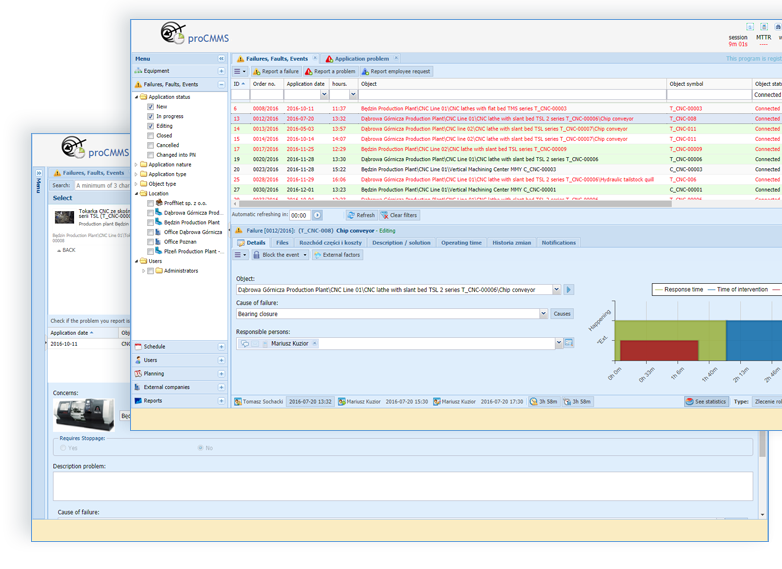

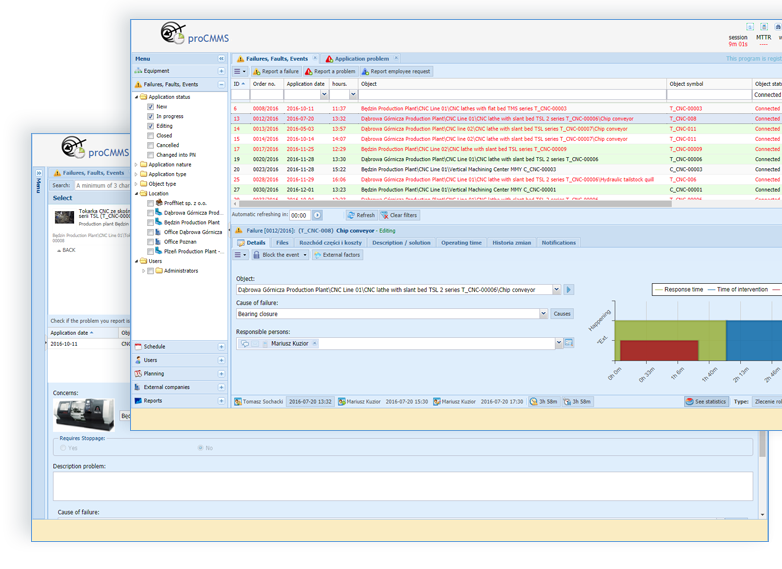

Handling system events and reporting repair process.

Failures, Faults, Problems, and Employee Applications

The system enables immediate reporting of device failure together with its description. Apart from the addition of a failure to the list, notifications are always automatically sent to the people responsible for this type of event.

Reporting repairs allows you to enter a description of actions taken, downtime, used parts and repairs performed on a given machine. Furthermore, selected users are informed about the state of the work carried out.

A list of individual machines’ breakdowns for any period makes it possible to identify the main sources of maintenance management costs. This allows the appropriate implementation of preventive measures in the future.

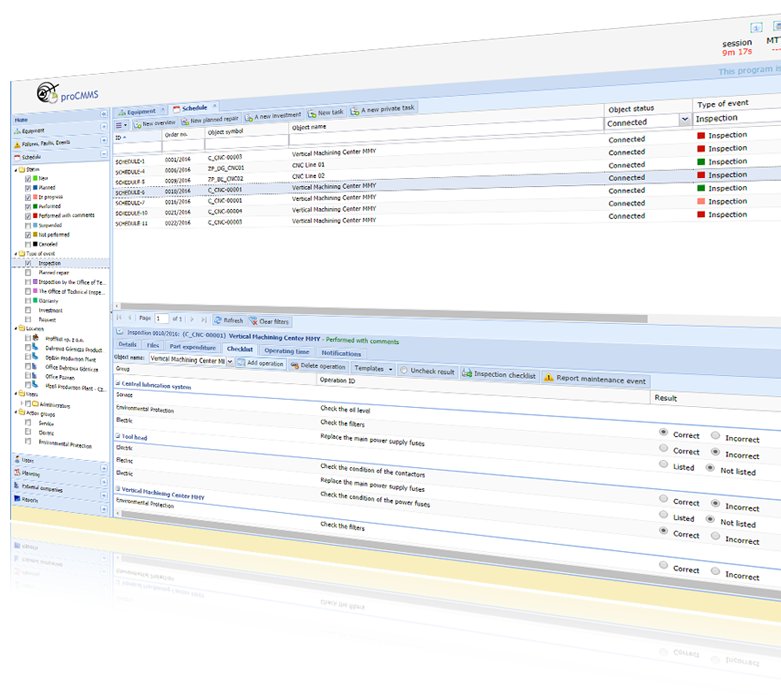

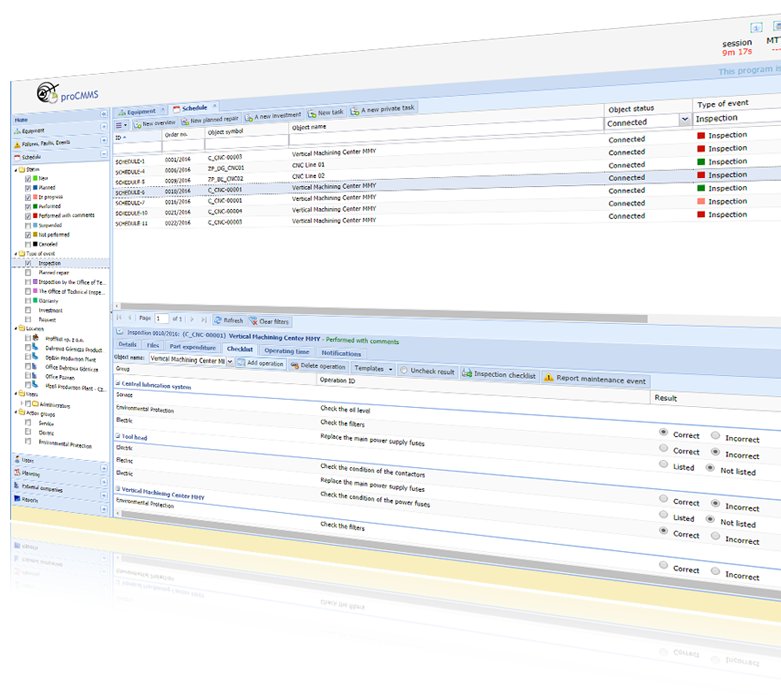

Work order schedule

Inspections, Overhauls, Repairs, Investment Planning, Inspections executed by UDT (Technical Supervision Office), Warranty Inspections.

Inspection schedule, in the form of an ergonomic calendar, clearly presents all the tasks planned by the maintenance management department. Thanks to colour tags, you can immediately see the work order schedule for the current week or month, as well as which orders have been implemented and with what result. This gives you a full view of the current state of the works carried out, even if some activities have not been carried out within a certain time.

Changing calendar view allows for a quick analysis of the schedule in terms of order types, the employees workload, and order location. All of this, together with the possibly to choose month, week, day or tabular view, allows quick view into both the current orders and tasks planned for the next year.

The schedule provides a clear overview of all planned activities and important deadlines such as planned overhauls and repairs, ongoing investments, reviews and rounds, information on upcoming UTD inspections, and expiration of warrantees.

The ability to handle recurring orders becomes indispensable when planning activities that are repetitive in a given period of time. Just define the scope of cyclicity and proCMMS Computerized Maintenance Management System will add subsequent orders after the implementation of the current one.

ProCMMS Planer included in the program is a convenient tool that can be used to manage the working time of employees. Due to the ability to assign specific orders to a given person, you can quickly check their workload and adjust the task schedule.

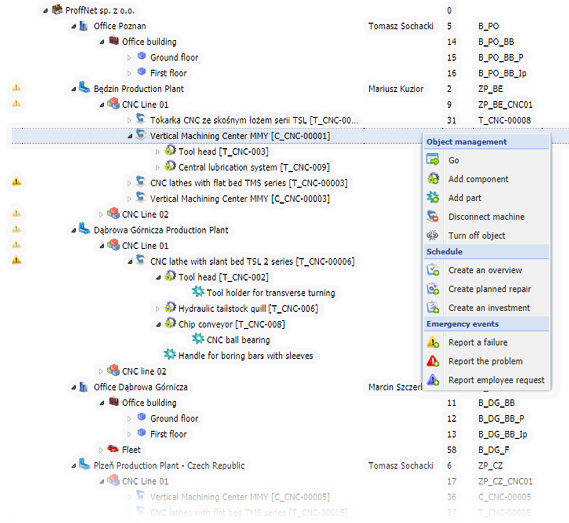

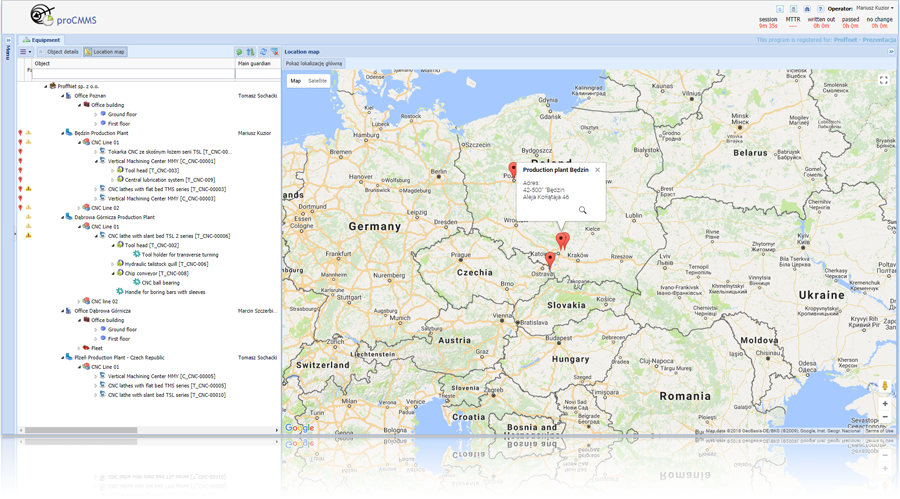

Multidivisional Organizational Structure.

Location Map, Production Lines, Manufacturing Cells and Sections, Machines, Subassemblies and Parts.

The location and equipment tree indicates the locations of plants, production lines, particular machines, subassemblies and spare parts. It is worth mentioning that the organizational structure of the company can be created completely freely and in accordance with the requirements and needs of your company. This solution allows for efficient management of scattered plants and machinery parks, defining warehouses of spare parts and assigning employees to individual branch structures. Another available feature is a convenient display of a map of individual locations.

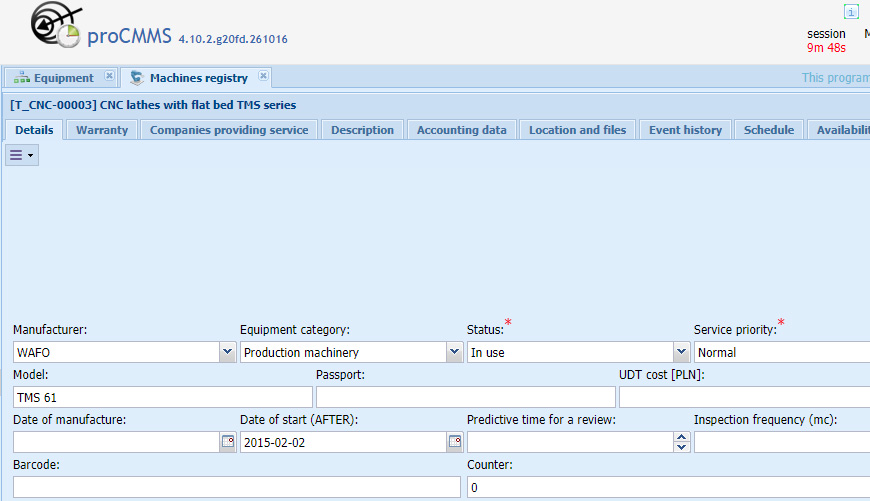

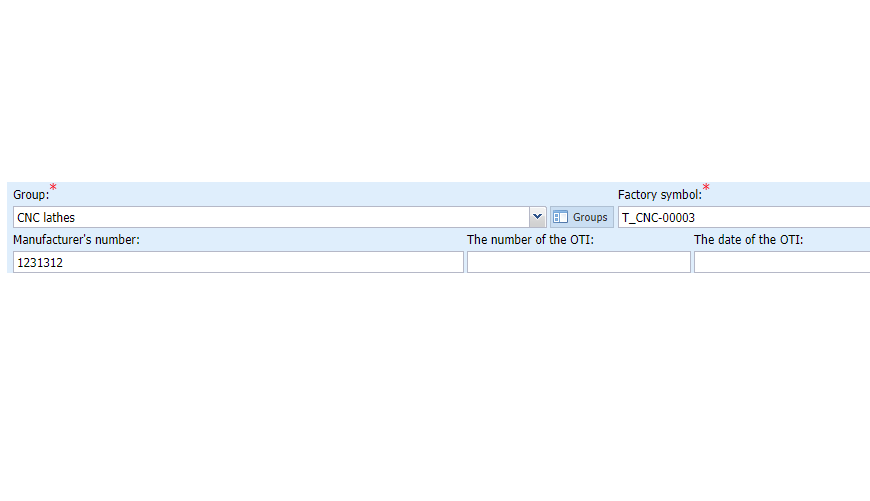

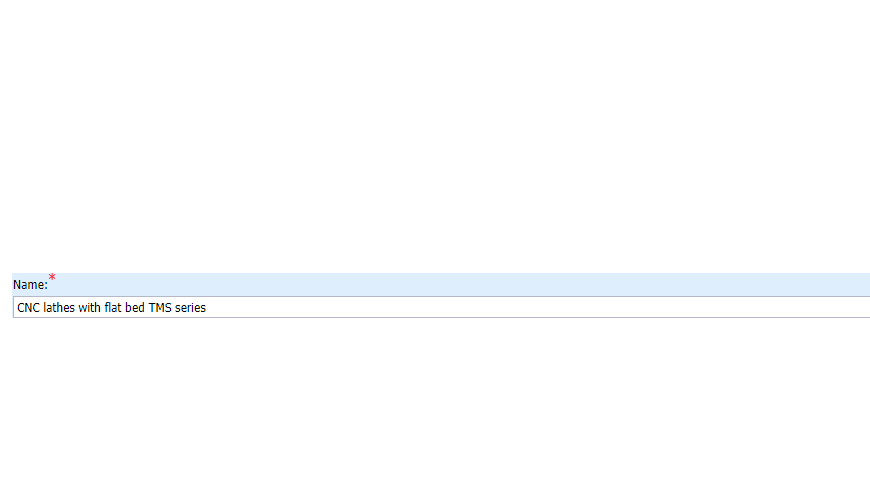

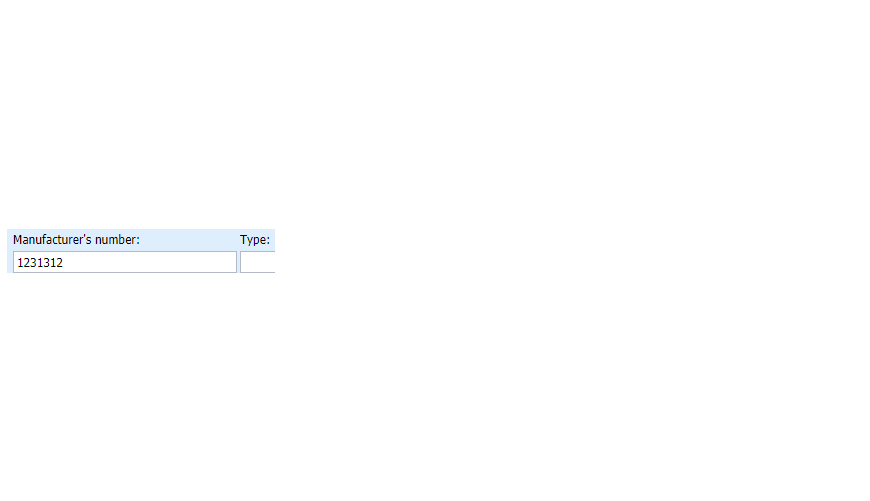

The register of machines and subassemblies constitutes a complete database of information about the machinery park in your plant. It includes important details such as name, symbol, description, inspection dates, UDT inspections, manufacturer, supplier register, accounting records, location, and photos. Each machine and subassembly also has a separate tab with history of its failures and other events, as well as a schedule of planned repairs and inspections.

The spare parts warehouse is the area of proCMMS, which acts as a management system for scattered spare-parts warehouses. This well-thought-out solution allows you to optimize and globally manage inventory in the entire enterprise. It enables, among others, monitoring the turnover of a given part in particular warehouses, creating a list of preferred suppliers, collecting technical documentation, and determining order delivery time. Moreover, it automatically sends notifications about exceeding minimum inventory levels.

Inspection Trails and Servicing Task List.

Precise plan of inspection and maintenance works ensures that no significant activity will be omitted. The Computerized Maintenance Management System generates a precise list of tasks for a specific production line, machines, or even subassemblies. In this way, you can determine the exact inspection trails grouped as part of one review order.

ProCMMS allows you to define ready servicing task templates for specific groups, machines, or subassemblies, and then assign them to a given type of inspection. Whit this, when creating an inspection order, you can select the correct set of service activities. You can also combine any task templates within one order.

The servicing task filter enables precise tracking of inspection orders related to a specific type of tasks performed. This function is of particular importance in documentation of obligatory tasks related to the company's procedures. Special cases are, for example, activities related to environmental protection procedures, ISO, warranty conditions, etc.

In a situation when the inspection does not result in a completion of all required servicing tasks, proCMMS system creates the so-called after-inspection event.. Thanks to this, you can be sure that the unperformed servicing tasks will not be omitted, but will be implemented on a different date.

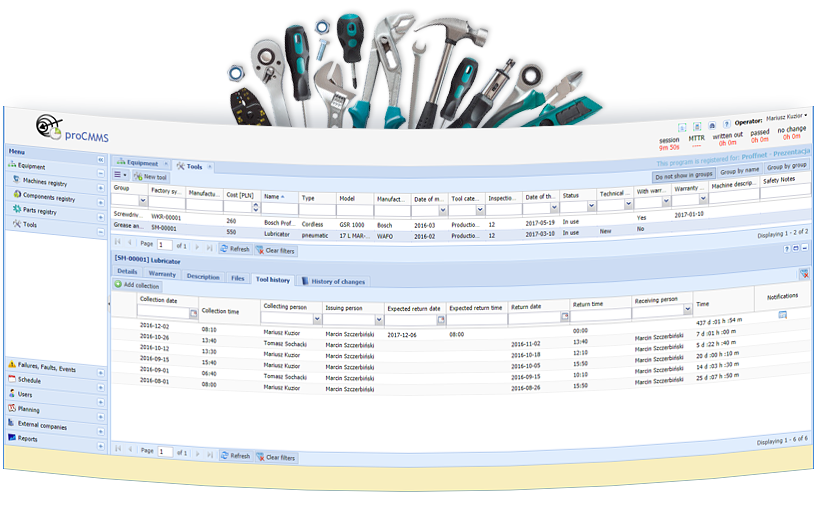

Tool Management.

The tool register provides full access to information about which tools the company has at its disposal and the way they are used. Rental and usage history reduces the risk of losing or destroying tools, by determining who is currently using them and when they should be returned. In addition, it allows you to set a reminder for users about the need to return a particular tool.

The tool register allows efficient management of maintenance works in the company. It provides information on, among others, the date of warrantee expiration, planned calibration, frequency of inspections. The document archive assigned to each device ensures that you will never have to look for a user manual and the warranty card will not be lost.

Third-party service

ProCMMS system has been designed to provide both servicing and maintenance management services in many scattered third-party companies, as well as management of the maintenance management department in an enterprise.

Access via any web browser and advanced authorization system provides every third-party company (client) with access to its own, specific data part. Thanks to this, you can report failures and events taking place at your machine park, run your own schedule of inspections and repairs, have access to detailed information on the work carried out, and service reports.

Each third-party company can be pinned to any place on the Equipment and Location Tree, which is also a filter for the Location Map in proCMMS system. It is an excellent tool to visualize the position of third-party companies and clients with a specific profile or those meeting the relevant search criteria.

The third-party company module also acts as a database of suppliers, manufacturers, external services and contractors for the other modules of proCMMS system.

Advanced Time and Attendance System.

A time and attendance system within and outside orders and events is a very complex module of proCMMS system. It allows to, among others:

- report accurate time and attendance procedures of performed works with their detailed description,

- plan and approve roster,

- plan holidays and time off in lieu,

- record sickness and other absences at work,

- record drive time, travel time and return time from an intervention,

- record uptime,

- determine allowances and delegations,

- indicate intervention works,

- and many more.

ProCMMS Computerized Maintenance Management System has a built-in editor of Working Time Types. With it, it is possible to precisely determine what types of work can be performed at specific events, orders and within defined time. Appropriate assignment of working time coefficient determines how this time will be included in individual reports.

Working Time Sheet is an excellent tool for analysing and forecasting working hours within a given month for individual employees. It provides information on the ratio of hours worked to the norm resulting from the calendar and a given month; overtime tracking; intervention works; duty shifts; compliance with norms on rest periods; the number of hours worked in a given working time type; the number of hours worked on particular types of orders; the number of works that are not included in working time; contact hours on given days, and details of the work performed. It allows you to manually correct and forecast the number of reported hours without affecting the original entries of employees and blocking entries in a sheet for a given month.

Individual views and filters, together with an extensive reporting system developed for the working time module, facilitate additional analysis of the entered data.

The mobile version complements the working time module with the possibility to organize individual works throughout their duration directly in a given order. The system ensures correct handling of working time recording on mobile devices even in offline mode. The synchronization of entries takes place automatically after logging to the Internet.

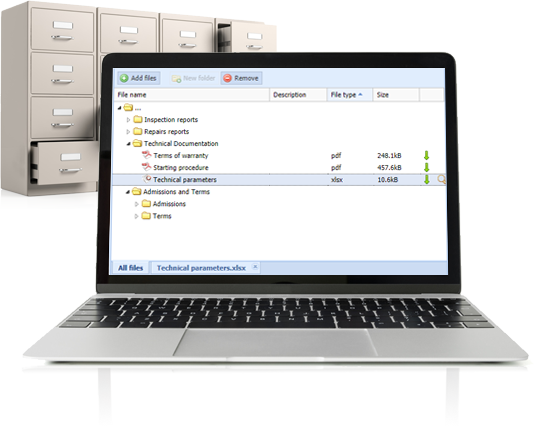

Document Archive and Active Spreadsheets.

Each module of proCMMS system has a universal solution that allows for fast and easy attachment of external files. Whether it is documentation regarding failures, machine manuals, or protocols from the inspection of entire production lines, thanks to proCMMS you can create any archives of documents assigned to specific system sections and objects.

Refreshing file contents allows you to attach a newer version of existing documents. Together with an active preview of spreadsheet files, this gives you the unique possibility to dynamically update views of frequently changing batch data. At the same time, the original formatting of data in individual files and spreadsheets is saved.

Automatic Notification System.

The notification escalation in proCMMS is an advanced autonomous system of sending information about almost every important event. Notifications can be delivered as a text message, e-mail, system messages to mobile and stationary devices, or be displayed in the program as information. Notifications are sent based on the default assigned level of responsibility for a given branch on the Location and Equipment tree. On this basis, the system distinguishes to which users, on which events and to which machines (or production lines) individual notifications should be sent.

Notifications of emergency events such as failures, faults, and problems are sent by the system immediately at the time they occur. In addition to the user group defined by default, proCMMS system also checks which employees are currently on call, so that the notification is also sent to those users.

Sending order notifications takes place in accordance with the schedule defined in the system. With this, it is possible to send relevant information at specified intervals before the start of the order. Default values for inspections, planned overhauls and repairs, UDT inspections and warrantee expirations are 14, 7 and one day before the planned order. A separate schedule of notifications can be set for each order.

The system also monitors and sends notifications about the minimum stock levels and the specified number of hours during which the machines worked.

Multilingualism.

Each user can be assigned a separate language of program interface. By default, the following languages are supported: Polish, English, and Spanish. However, you can change the language with two clicks. All you need to do is to export the language file, send it to the translation agency, and upload the translation.

Multilingual support is also a unique opportunity to change the terminology used in the program, i.e. to translate from Polish into Polish.

WELL-ADJUSTED

An intuitive Computerized Maintenance Management System that will adjust to your needs.

WELL-ADJUSTED TERMINOLOGY

PERSONALIZATION OF SETTINGS

FLEXIBLE TABS AND FORMS

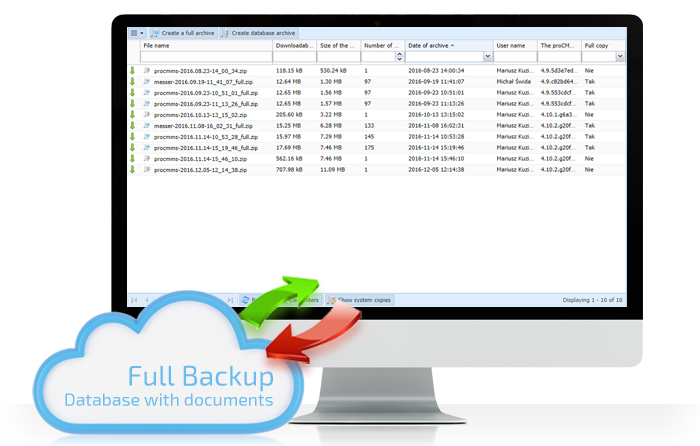

SAFE

A reliable system that you can entrust your most important data with.

AUTOMATIC BACKUPS

AUTOSAVING AND DATA VALIDATION

DATA ENCRYPTION

FULL OPERATION RECORDING

DYNAMIC

An efficient system that keeps up with the development of your company

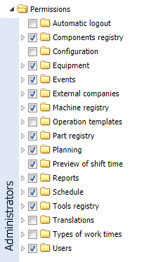

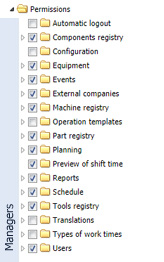

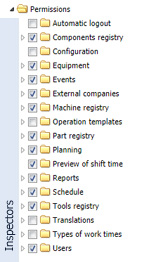

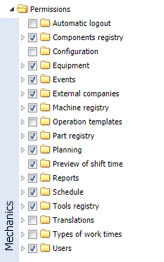

A PRECISE ACCESS MANAGEMENT SYSTEM

OPTIMIZATION OF YOUR DATA LINK

FAST INFORMATION RETRIEVAL

In the mobile world, maintenance management requires access to mobile tools.

ProCMMS system is a friendly, intuitive tool also available on your phone or tablet. With it, you can:

- receive notifications and alerts regarding your machinery park,

- send and receive messages from the system’s instant messenger,

- synchronize the calendar in your phone with the servicing task schedule,

- inform about the work carried out on individual events in real time,

- confirm reception of failure notification and start of intervention,

- indicate the completion of work on events and the machines uptime.

Moreover, you can work with proCMMS even without an Internet connection. The system will synchronize all data as soon as it is connected back to the Internet.

We have gained the trust of

Since 2002, the list of our satisfied clients has been expanded by:

Trial implementation

ProCMMS seems interesting to you, but you are not sure whether it will work in your company? We perfectly understand that the suitability of the chosen system is best checked in realistic conditions.

That is why we have prepared a Lite version of proCMMS that is fully functional, without any usage time restrictions. For only a net price of PLN 55 per month, this version of the program gives you the possibility to add 2 users and 120 machines, as well as provides you with an access to the latest updates.

That is why we have prepared a Lite version of proCMMS that is fully functional, without any usage time restrictions. For only a net price of PLN 55 per month, this version of the program gives you the possibility to add 2 users and 120 machines, as well as provides you with an access to the latest updates.

If you decide to implement proCMMS system in your company, the upgrade to the full version will only take a few seconds, and you will be able to leave the previously entered data in the full system version.

Fill out the order form and get unlimited access to the trial version of proCMMS system. If you decide to use the full version, the cost of trial access will be deducted from your first invoice.